Software development is one of the biggest and most flourishing markets of the 21st century. Owing to the growing dependency on various types of software, be it smartphones, mobile apps, various smart household appliances, or industries, the demand for software development is on the rise.

Today every industry around the globe is heading to trusted software development companies to develop the software of their needs in minimal time and costs.

Over time, various breakthrough technologies have been integrated into different software to make services more convenient. These technologies include Artificial Intelligence & Machine learning, Blockchain technology, IoT, GPS, RFID, and many more.

In this post, we will talk about AI, one of the most revolutionary technologies of the 21st decade. We'll discuss ways artificial intelligence in software development can transform the manufacturing industry by streamlining operations and boosting overall productivity.

Let's move forward and start by getting an overview of AI.

A Brief Overview of AI

Artificial intelligence doesn't need any overview, as it's impossible for a tech enthusiast or a techie not to be aware of AI and how it has transformed the world. Every other day news related to AI or a related innovation keeps making headlines worldwide.

AI is a flourishing market, and according to Statista, the AI market size is poised to cross half a trillion dollars by 2024 and reach 1.5 trillion U.S. dollars by 2030. The AI market size is so big that it is larger than the GDP of most countries.

The implementation of AI is transforming almost every industry operating today. Some sectors changed the most by AI technology are healthcare, cybersecurity, financial services, pharmaceuticals, education, and manufacturing, among many others.

One of the most common reasons these sectors invest in AI-powered solutions is their efficacy in improving the productivity and quality of various operations. These operations might be either too tedious or repetitive for human beings to perform or those requiring utmost precision and calculations.

How Can AI in Software Development Transform Manufacturing Industry?

Manufacturing industries have many repetitive tasks that, when done by humans, are pretty time-consuming and unproductive. These repetitive tasks don't require creative thinking, making the workforce lose creativity and efficiency over time.

Today manufacturing industries have started using software for carrying out redundant and time-consuming tasks in lower time and with better precision. Thus allowing the related workforce to work on more creative tasks that boost their productivity and help them learn new things.

The implementation of technologies like artificial intelligence in various software operating in manufacturing industries has made machines more smart, efficient, and self-decision-making.

Let's check out how AI-driven software will transform manufacturing industries.

#1 AI in Robotic Process Automation Software

Robotic process automation is one of the manufacturing industry's most effective and revolutionary solutions. Also known as RPA, it has proved revolutionary in boosting automation, streamlining various tasks, and making redundant tasks hassle-free.

RPA is software where bots are created/programmed to perform particular tasks. These software bots need to be programmed and taught beforehand what they need to perform, and once they are loaded, they mimic human actions and complete the tasks the same way humans would but faster and more precisely.

Magic of AI in RPA

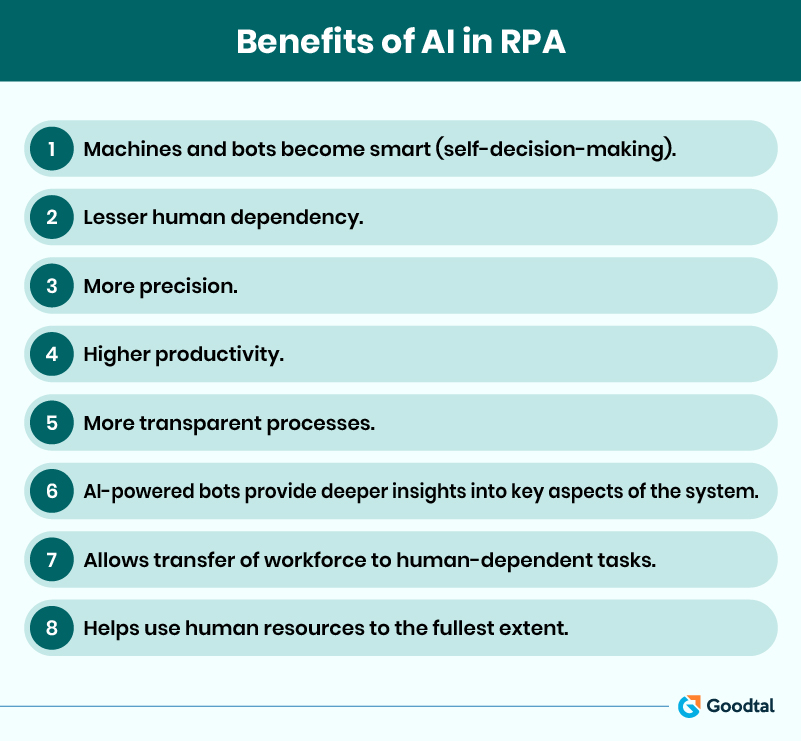

Artificial intelligence is a technology that can make machines think like humans. AI is known to educate itself from its experiences and the different kind of data it is being provided. Just like humans, AI learns from its experiences, and this is the main feature that bolsters RPAs and makes them function much better with human-like intelligence.

In robotic process automation, software bots are preprogrammed with every detail to work on the appointed task. But with AI implementation, the system can free itself from human dependency and be made capable of making its own best decision in times of need. The forged alliance of RPA and AI is also known as Intelligent automation.

The combination of AI and RPA can provide better insights into various operations to the authorities. For example, consider inventory management with intelligent automation; you can always maintain the optimal inventory quantity. AI will provide better insights to the authorities related to inventory by accessing records and considering every scenario.

Based on a study by Deloitte, the top decision-makers anticipate that intelligent automation will help reduce the average production cost by 22%. This significant finding has led manufacturing industries to invest more in intelligent automation and reap its benefits.

Suggested Reading: The Future of Software Development: Will AI Replace Human Developers?

#2 Predictive Maintenance

Predictive maintenance has become one of the hot topics in manufacturing industries these days. Routine check-ups and maintenance of machines are crucial in manufacturing industries, where even a tiny problem in a particular device can end up creating a line of defective products.

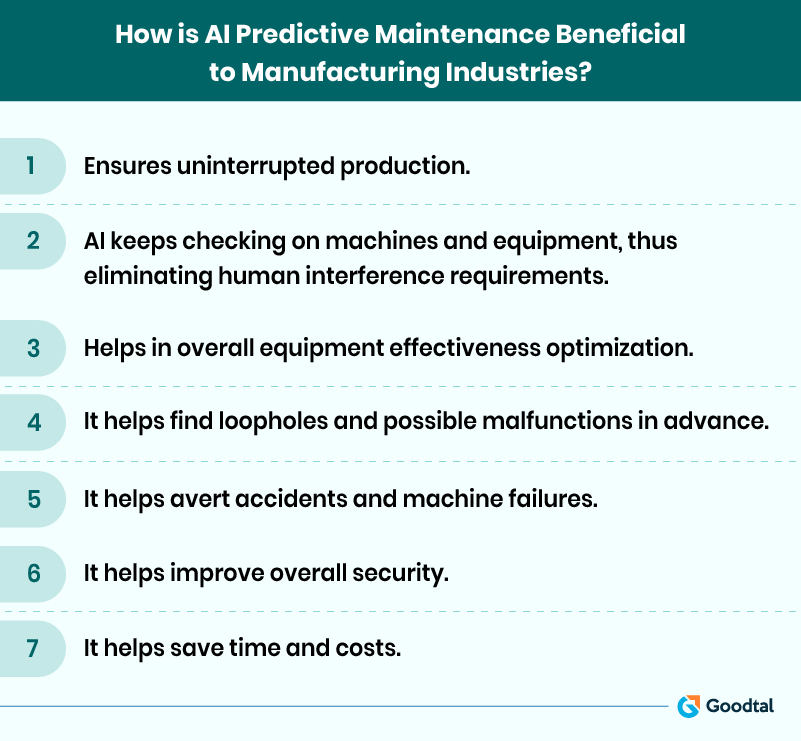

Predictive maintenance refers to the use of technologies, AI in general, to alert authorities in advance related to issues such as malfunctioning of the machine, quality defects, and the need for maintenance so that it can be handled before breakdown. This way, uninterrupted, continuous, and quality production of goods can be ensured by maintaining machines and doing repairs at the right time.

According to Deloitte, predictive maintenance can boost productivity by 25%, reduce machine breakdowns by 70%, and reduce maintenance costs by 25%. Now, let's get an overview of AI for predictive maintenance.

AI in Predictive Maintenance

AI is one of the core technologies powering predictive maintenance. All kinds of data related to machines, such as the optimal noise coming from them, vibrations they make, the power they are dissipating, etc., are accessible to AI. AI continuously monitors the mentioned parameters and alerts authorities when abnormalities or diversion from mean values is sensed.

Hence, authorities can avoid future mishaps by following these alerts and addressing them in advance. This is the key objective of predictive maintenance; to predict, alert and help authorities address problems before time.

Looking at the efficacy of predictive maintenance, more and more industries are adopting it. This demand has made predictive maintenance a flourishing market. According to reports, the global predictive maintenance market is expected to grow significantly and reach 64.3 billion USD by 2030, up from the 5.7 billion USD reported in 2021.

#3 AI-Enabled Generative Design

"Machine learning allows us to build software solutions that exceed human understanding and shows us how AI can innervate every industry."

Steve Jurvetson, Board Member of SpaceX and Tesla

Steve Jurvetson's thoughts on AI and ML seem to hold truth as AI and ML today can be found in every industry, making things easier wherever they are employed. One such revolutionary example is AI-driven generative design being widely used by top manufacturing industries, be it automotive, electronics, or shoe manufacturing.

AI-driven generative design involves using AI in engineering and design to simplify these two processes and build sturdy product designs. As we know, AI & ML can learn from records and experiences. Hence using this feature, AI helps engineers and product designers develop unique and flawless designs.

One of the most popular use cases for AI-driven generative design is General Motors. Using AI-driven generative design, the engineers at GM came up with a seat bracket design that was almost 40% lighter and 20% stronger than the previous ones. Today General Motors is heavily using generative design in all of its new vehicle designs.

Another example of successful generative design use cases was witnessed in WHILL, a Japanese electric vehicle manufacturer. Using AI-driven generative design software, they were able to design a more compact motorized wheelchair. Engineers at WHILL, using a generative design, made it possible by reducing the weight of the heaviest part, the battery case, by 40%.

Businesses looking forward to leveraging AI and developing AI-driven software must check the list of top Java developers, AngularJS developers, ReactJS developers, and others on Goodtal to outsource their work to some of the trusted developers around the world.

Summing Up

Software have become a very important and one of the most common things we can find in our surroundings every time. With the implementation of up-and-coming technologies, software have become more revolutionary and have transformed every industry present today. One such technology is AI which has been transforming every industry it is being implemented in.

In this post, we focused on AI and the manufacturing industry. We discussed how the manufacturing industry is being revolutionized by AI-based software and how they benefit. Using AI manufacturing industries not only can automate and streamline various processes but also can help use the workforce more efficiently.

Moreover, using AI-powered solutions in manufacturing industries can save a lot of time and costs. These industries can further use the saved time and money to start new ventures and scale their business.